Scientists from Carnegie Mellon University in the United States have developed a novel 3D printing process and successfully manufactured micro delta robots named microDeltas. These robots are expected to play significant roles in fields such as micromanipulation, microassembly, minimally invasive surgery, and wearable haptic devices. The relevant research paper has been published in the latest issue of the journal Science Robotics.

Delta robots, also known as parallel robots or parallelogram robots, are high-speed, light-load parallel robots. Their robotic arms are composed of three parallel support rods and adopt a parallelogram structure. They are widely applied in areas including food packaging, pharmaceutical sorting, electronic assembly, and new energy vehicle die-casting processing.

As early as the advent of microelectromechanical systems (MEMS) in the 1980s, engineers envisioned using them to manufacture micro robots. The laws of physical scaling also suggest that miniaturized robots have the potential to achieve breakthroughs in terms of speed and precision. However, limited by the micro 3D manufacturing technologies of the time, scaling robots down to microscopic sizes was no easy feat.

This time, the team developed a 3D printing process based on two-photon polymerization. This is an advanced nanofabrication technology that precisely cures photosensitive materials by focusing laser beams. After that, a thin layer of metal is deposited to create complex 3D structures and actuators with electrical functionality, eliminating the need for manual folding or assembly.

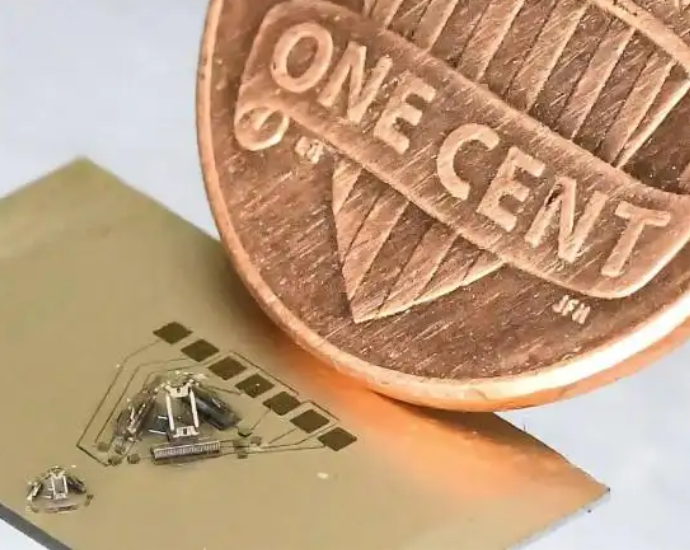

Using this technology, the team manufactured micro delta robots with heights of only 1.4 millimeters and 0.7 millimeters. Compared with similar robots, they are the smallest and fastest to date. Experiments have confirmed that reducing the size not only enhances the robots’ precision to the sub-micron level but also enables them to operate at frequencies exceeding 1 kilohertz. They can even launch salt particles equivalent to 7.4% of their own mass.

The team stated that with the aid of 3D design and printing technologies, they completed eight design iterations of the robots in a very short time, whereas traditional methods might have taken weeks or even months. In the future, by adjusting design parameters, constructing large-scale arrays, or introducing sensory feedback, the bandwidth, precision, and working range of the robots can be further improved.